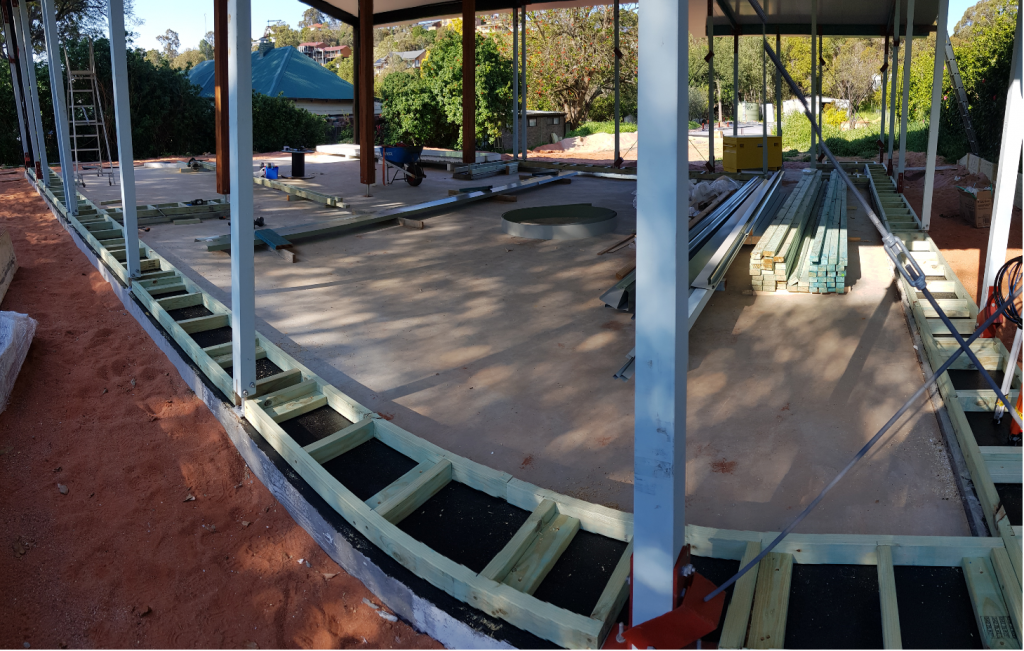

Had two (TWO!) helpers for the day, so we smashed out the entire bottom plate for all the shed’s bale walls: Not a huge amount to say about it – it’s not overly complicated, just a lot of short pieces of timber and a lot of screws holding it all together.

My helper for the day foolishly admitted to enjoying painting (which is something I don’t enjoy at all) so I put her to work finishing off the steelwork over the carport. Looking right purdy now. Also got started on the bottom plate below the bale walls…not a lot of progress, but cut all the side pieces at least.

The shed roof, as originally specced, was supposed to be 16m long along the ridgeline. At some point though (ie. when we changed the carport structure from timber to steel) the extended rafters to support the last bit of roof got deleted, so I had to make a couple of half panels or else risk the last panel flapping in the breeze. So with much measuring, double-measuring, freaking out, checking with my helper for the day and freaking out a bit more…

Bowed to the inevitable (by which I mean “my regular helpers threatened to unionise and go on strike if I tried to do the rest of the roof with materials hoists”) and got a crane in to do the rest of the shed roof panels. Very productive day, where we ripped through the 24 remaining panels in about 6 hours. The crane (a small’ish Franna) and its people were really good – I’d half expected them to wait for us to do everything except the…Continue Reading “Crane goodness”

So my critical path, in so much as I have one, has been to get a roof up so the farmer holding my bales can get them out of his shed and into mine. With the frame functionally complete I could finally start working on the pile of roof panels. A mate dropped around for a couple of hours to get the first pile of panels on the slab, and helped get the first ones prepped. I’d expected progress to be really slow today, and…Continue Reading “The roof! The roof! And it’s not on fire!”

The last big beams to get up were the three connecting the timber shed frame to the portal. These were all small (hah!) enough to do with one lift, but it didn’t go quite as smoothly as hoped – dramas with bolts, holes, flanges and other fun things. Beams had to be trimmed (I ordered them a little long to cover against 10mm variations either way), holes drilled in steel, lots of working at heights. End of the day we got the three beams up:…Continue Reading “Lifting day 2”

One of those days where you don’t get a lot done in terms of raw numbers, but it was definitely a good day. Gathered two materials hoists (wonderful things that they are) and some scaffolding to get the main shed beam installed. This beam started life as a 450×85 LVL, and during some back and forth with the engineer changed into a 450×83, a 450×63 and then a doubled 450×63. The single beam would have technically worked, but the engineer sounded marginal about it and…Continue Reading “Lifting Day”