My architects had, in all their spare time, gotten involved in an architecture course at UWA, and asked if they could bring some students around for some practical experience and….y’know….actually set foot on a building site, which is apparently a novel concept? 🙂

After a few delays and dramas along the way, this weekend turned out to be The One. I’d earmarked the front wall of the shed for this weekend, since it was straight (which reduces the amount of bale weirdness) but had four windows in it for a bit of variety, and if we didn’t finish it would be easy enough to finish off later.

Day 1

Our crowd of willing newbies rocked up on Saturday – mostly students, with one of Deepti’s colleagues and a couple of extras. Deepti did an excellent job of explaining the whole theory, I demonstrated the official ways of mutilating bales and away we went – split into two groups and worked from each end of the wall at the same time.

Progress was pretty steady, and by the end of the day we had most of the wall at or above the level of the windowsills, and all the window frames in place and tied down to the bottom plate. (forgot to take photos, because I’m a twit)

Day 2

Mostly a new crew of newbies, but with Deepti’s colleague back for a second go. We left the students to Deepti at one end and tackled the fiddly bits up and over the three windows – The pillars between each window were all a very-convenient full bale wide (completely by accident), but the height was not an even multiple of a bale’s height so we had to cut a bunch of small bits to bring everything back to level. Of course all of this was ~2.4m off the ground, to add to the fun.

Towards the end of the day it looked like we would probably be able to finish the wall and get it tied down, so we pushed on a bit past 4pm. A group effort to get the last few bales notched, cut and placed, threw the top plates up, undid all the looped-up straps, threw them over and buckled them down.

The Wetjens had brought their strap tensioner with them – interestingly, despite using completely different straps to me (and crimped, not buckled), their tensioner was interchangeable with mine. So we could work our way down both sides of the wall at once, tensioning alternate straps to each side.

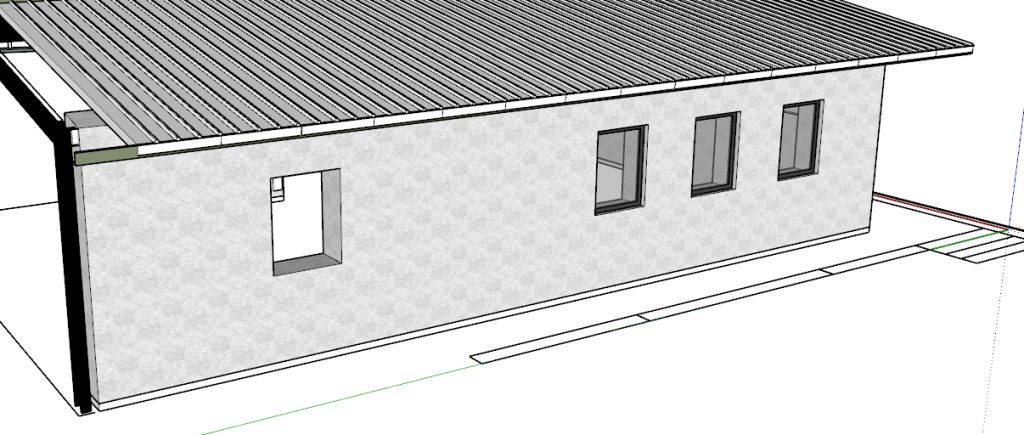

The end result was pretty impressive for a weekend’s work: