My sparkie had some….residual unhappiness….about wiring the house roof panels – I’d avoided this in the shed by simply not having any lights mounted in the roof panels. Apparently in the past when working with SIPs he’d done the wiring as the panels were being put up, which seems…overly difficult, and would also slow down the install significantly as you muck around with each panel (all while working up ladders, of course). So out came my 3d model to work out where each light needed…Continue Reading “House roof – pre-wiring”

Got the first coat onto three walls of the inside of the shed over the last few days: The last few sessions I’ve been doing 4 or 5 mixer loads, rather than 8-9, and that seems to be keeping the worst of the lime burns at bay – not sure whether I get careless as I get tired, or if it’s just a gradual buildup of lime over time. One change I did make was to tweak the order of mixing each batch to put…Continue Reading “More inside rendering”

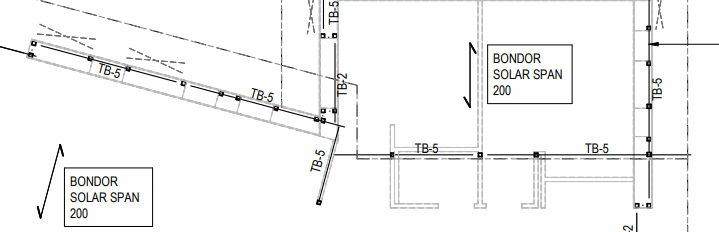

Where did my slab go? I’m sure it was here earlier, but now there’s just piles of SIPs all over the place. I’ve arranged for the house panels to come in in two deliveries, because I simply don’t have enough room to store them all on the slab given that I have to lay a fair few of them out to be wired.

Fun afternoon tweaking the door frame for the wet-area access from the east side of the shed, to fit a door I found in a salvage yard – I figured having some glass in this door would be nice, to add light to the wet area. Of course I then managed to leave the doors leaning against a post on a windy day, the wind blew them over and put a door handle through one of the panes. I’ll have to get that replaced at…Continue Reading “A door!”

Short, fast and tough bit of rendering, working on the inside back wall of the shed. Didn’t take us very long, but a combination of hot weather, me changing my mix ratios and getting render clumped up in the mixer, sweat and clumsiness meant I clobbered my arm a bit with lime burns. Nice to get a serious bit of internal wall done though: Meanwhile the sparkies were finishing off the switchboards ready for the meter to be moved into its final home on the…Continue Reading “Inside rendering”

Something I’d wanted to experiment with was cram-walling – the unofficial name for internal straw walls, with wire mesh stretched over the stud frame, the void filled with loose straw and then rendered. There’s only one internal wall on the shed, between the dusty room and the wet area, which seemed like a good excuse to try this method out. We’d put a simple stud frame up a couple of weeks ago, in between other tasks: So I stretched some small-diameter chicken wire over this…Continue Reading “‘Cram’ walling”

The last three beams up, alongside the hallway and a small one over the study. There’s a bit of steel framing to go around the big windows on the NW corner of the living room, but the roof framing is more or less complete.

With the big stuff done, and the genie lift returned, we did some more smaller beams by hand. This was actually pretty easy – we could just lift one end into the bracket, then hoik the other end up using a platform ladder. The main advantage of the house over the shed is that the beams are shorter, often smaller and therefore very much lighter. Of course there’s more of them…. Got the front door, entrance, kitchen wall, west wall and east wall beams in…Continue Reading “Lifting smaller beams”

Had the lift for the rest of the weekend, so hoisted up the other big beam – a 270×45, 7.5m long one that spans across the kitchen, and its companion that has the cross-bracing to hold it upright. This was the only time I’d done any lifting alone – had to slow down a LOT and do the lifts more carefully, without having someone on the lift and someone to steer the beam, but got it done with no mishaps.

Somewhat brutal day with a genie lift, lots of bonus hands and a 37° forecast. Started with lifting and cross-bracing the angled beam in the NW corner, to hold the ridge beam post upright. Then had to bring up the two beams on the north side of the living room, because they support a short beam that butts into the side of one of them. The ridge beam then butts into that short beam. The first three went up pretty easily. The ridge beam turned…Continue Reading “Lifting day”